Case Study: Rambo Drill Cycle Time Reduction

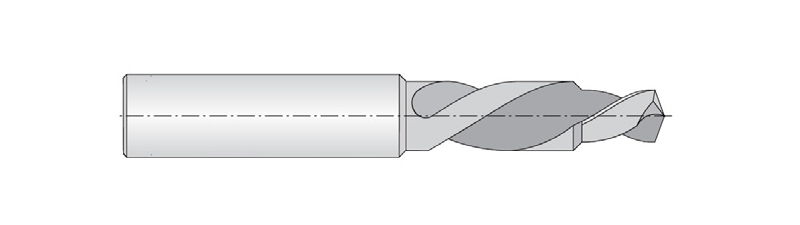

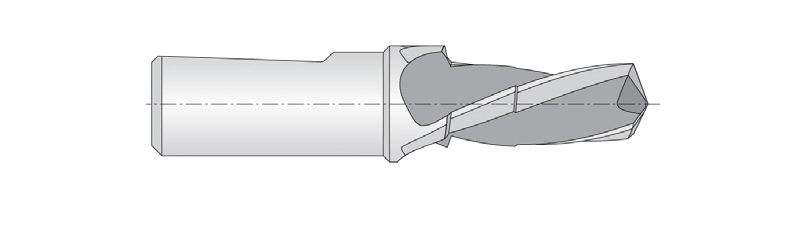

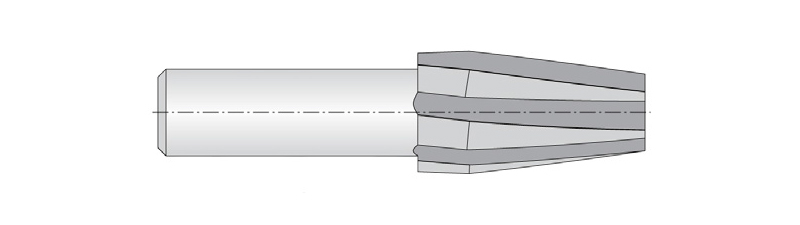

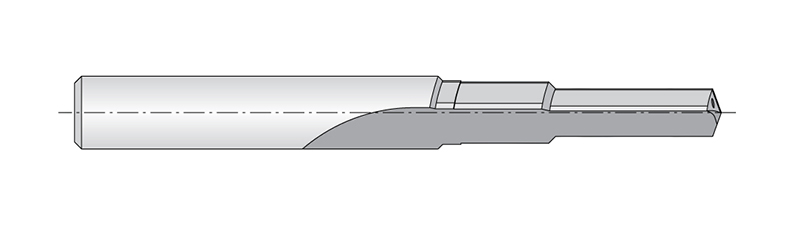

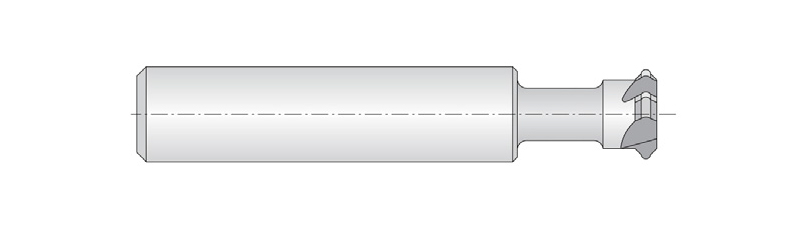

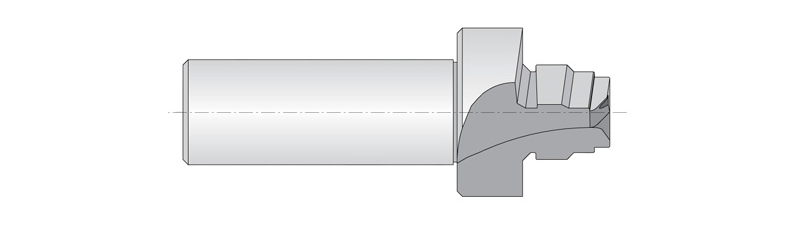

SUMMARY OF RESULTS Tool Reduction: 2 to 1 5 Second per part cycle time reduction Yearly Cost Savings: 312 Machining Hours! THE CHALLENGE A manufacturer…

With decades of experience in the most demanding applications, MK Tools offers excellent application-specific tooling. They offer individual solutions to challenging applications with rapid and reliable lead times. If have application you would like to discuss with us, contact us here!

Get the latest news, offers, and machining resources from your hole finishing experts by signing up for the Monaghan Tooling Group mailing list:

30 N. Clinton Street

Dayton, Ohio 45402

Toll-Free: 1.800.732.4565

Phone: 937.253.7706

Fax: 937.723.7702