Case Study: IRU Hydraulic Valve Bodies

SUMMARY OF RESULTS

- Time Savings: 8000%

- Machining Time Reduction: 19 minutes to 15 seconds

THE CHALLENGE

One of our customers was manufacturing hydraulic valve bodies made of Cast Iron grade 250 using a CNC horizontal milling machine. The valve bodies required recess in (8) positions, and previously the customer used a carbide cutter to interpolate each of the recesses individually. This was extremely time consuming with a cycle time of 20 minutes per bore.

OUR SOLUTION

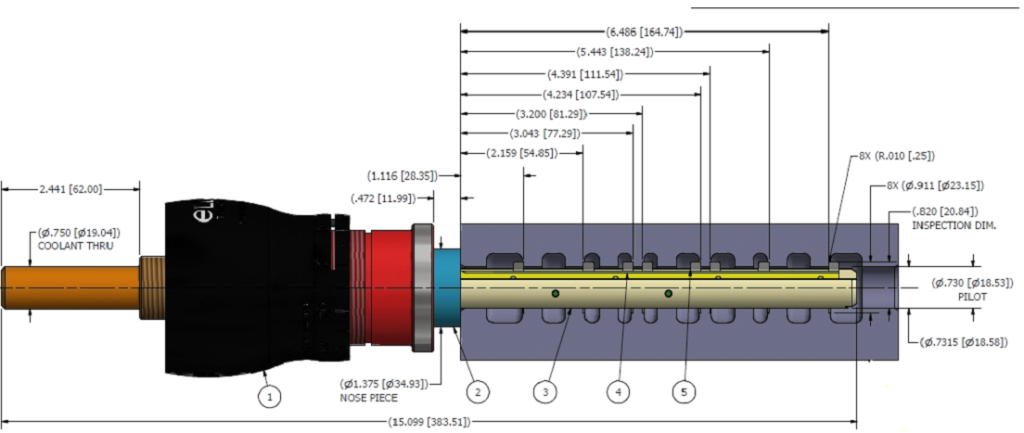

After assessing our customer’s problem, we decided to recommend our Internal Recessing Unit. Here are the statistics of our IRU recessing operation:

- Speed: 300 RPM

- Cutting feed: 0.003”/rev (0.76mm/rev)

- Total cycle time: 15 seconds

- Tool life: 600 bores before regrinding

FINAL RESULTS

The IRU recessing system produced all (8) “land face” cuts in 1 pass, maintaining the 0.003” (0.07mm) positional tolerance between the grooves. The time savings was 19 minutes and 45 seconds or an 8,000% time savings. This time savings eliminated the need for our customer to purchase another expensive CNC horizontal milling machine.

- Time Savings: 8000%

- Machining Time Reduction: 19 minutes to 15 seconds