Challenge Details

- Slow & inconsistent results from a competitors reamer

- Poor surface finish from chip balling

- Material: 1045 Steel

Objective

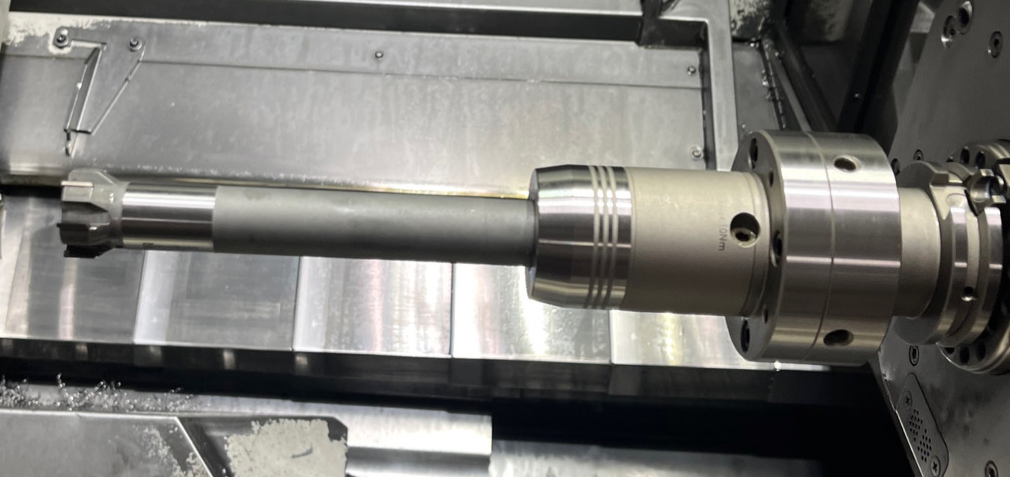

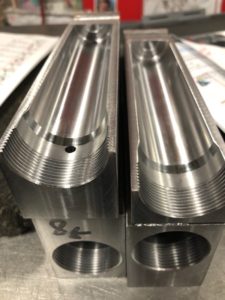

Propose a solution for machining ∅1.2475″ (31.673mm) bore on a hydraulic part in a horizontal mill. Previously, this was accomplished with a solid carbide reamer at 37 seconds per part.

The Solution

Monaghan proposed the use of a Diatool monoblock expandable cermet reamer with a module 80 compensation holder. The Diatool reamer ran at 1500 RPM and 50 ipm with a new cycle time of 7 seconds.

Overall Results

- 30 second cycle time reduction

- CPU - reduced

- Consistently removed more material allowing for a 2.5x faster honing process

- Chip control - reduced chip balling at the bottom of the bore

Benefits Realized

Cycle Time Saving

The Diatool reamer reduced the cycle time by 30 seconds.

Consistent Results

The Diatool solution removed more material which allowed the honing process to be about 2.5 times faster!

Chip Control

The solution helped reduce chip balling which was hurting part quality.