PRODUCTS

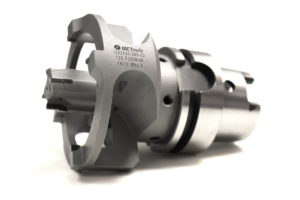

Diatool, is an industry leader in reaming technology. The proven geometries of DIATOOL high performance reamers produce precision bores at much higher feed rates than single-point tools – reducing cycle time and total cost of ownership.

MK Tools endeavors to provide the best cost-effective and time-saving solid carbide solutions for your applications. Innovative designs and the latest generation of CNC grinding machines ensure solid carbide standard and special tools achieve the highest performance and quality possible.

DRILLS

ENDMILLS

RAMBO DRILL

AXIS is the world’s leading manufacturer of high precision tools for micromachining. Innovative standard and custom microtooling as small as Ø 0.03mm. Ultra-precision AXIS drills, endmills, engravers, routers, tapered tools, and reamers – stock and custom special tools for micromachining applications.

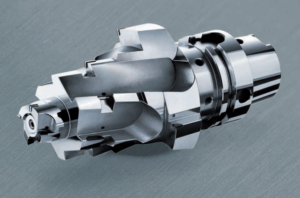

UC Tools specializes in providing highly engineered PCD solutions for the machining of complex aluminum components – consistently delivering a high quality product with short lead times, for both new and reconditioned tools.

RE-AL, has over 50 years of focused experience that sets them apart in the world of precision HSS-E reaming. With their deep flutes and proprietary coating, ACUREA, they are able to exceed the cutting performance of solid carbide jobber reamers.

ADDITIONAL PRODUCTS

- Adjustable compensation nut from Reamtec.

- Compatible with all ER collet chucks – sizes ER16 to ER40.

- Minimize runout for any round tool.

- Priced to belong in every machinist’s toolbox!

- RE-AL compact floating holders with parallel axis for accurate position and self-centering.

- DIATOOL floating holders with factory-set, true 360 float made possible by cylindrical roller design.