MK Tools Speed Drill:

PRECISION, SPEED & OPTIMAL PERFORMANCE

MK Tools Speed Drill Series

Welcome to the frontier of cutting-edge manufacturing technology! MK Tools understands the intricate needs of modern engineers. That’s why they have crafted the Speed Drill Series of solid carbide drills, tailored to deliver unmatched precision, speed, and longevity. Unlock the potential of your projects with MK Tools – where precision meets efficiency.

Why Choose the Speed Drill Series?

This series offers a diverse range of solid carbide drills for long-lasting performance in high-speed applications. Here are some of the key features of our drills:

STANDARD SIZE RANGE:

∅ 3.00mm – 20.00mm

AVAILABLE LENGTH:

3xD – 12xD

HELIX ANGLE:

30° Right Helix ensures efficient chip evacuation.

CUTTING DIRECTION:

Right Hand Cut for standard machining applications.

POINT ANGLE:

140° with a relieved cone for optimal centering.

GTX – high wear resistance.

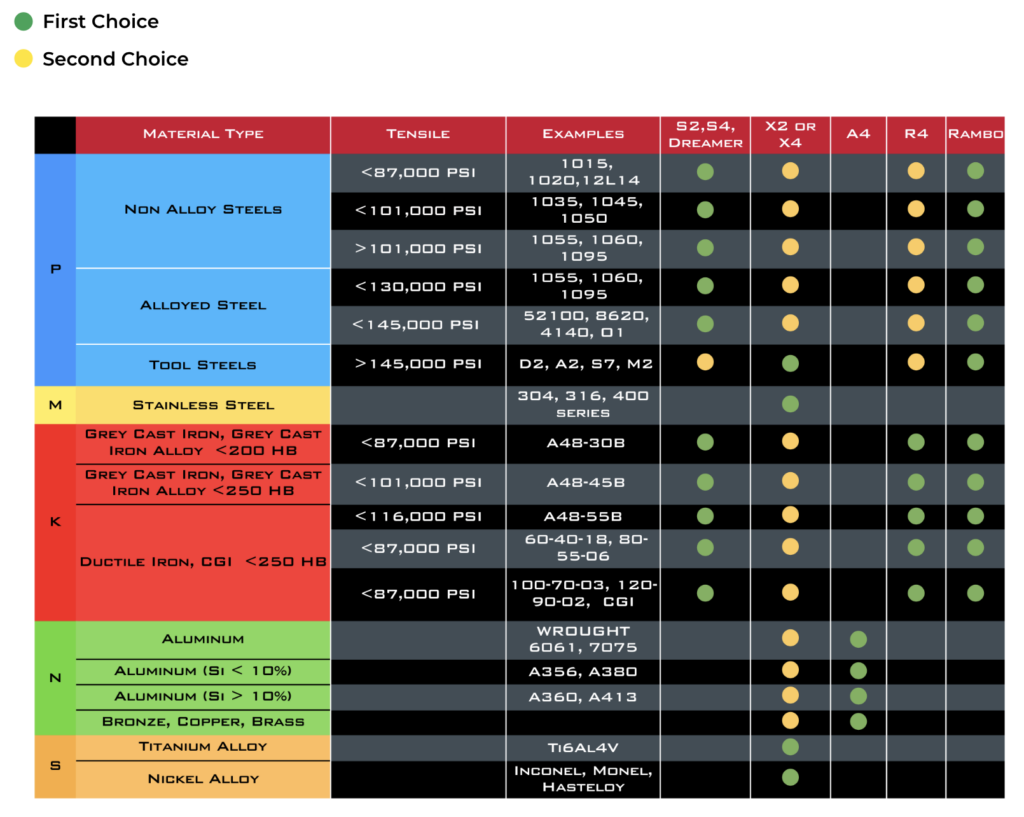

Applications: Ideal for a broad range of drilling tasks, offering versatility with its 2 guide lands. Particularly suited for unalloyed or alloyed steel applications where general high-speed precision is required.

Materials: Unalloyed Steel, Alloyed Steel, Cast Steel, Gray Cast Iron, Ductile Iron

Speed-Drill S2 Options:

• 3XD or 5XD

• Coolant thru or Non-coolant fed

Applications: Designed for deep hole drilling tasks where hole quality is paramount. The 4 guide lands provide enhanced accuracy, ensuring exceptional roundness, straightness, and tight tolerance in various steel and cast iron materials.

Materials: Unalloyed steel, cast steel, alloyed steel, cast iron

Speed-Drill S4 Options:

• 5XD or 8XD

• Coolant thru or Non-coolant fed

Applications: Optimized for challenging materials like stainless steel, titanium, and nickel alloys. The 4-facet point coupled with 2 guide lands delivers a balanced performance for these harder alloys, ensuring reduced wear and improved hole quality.

Materials: Stainless Steel, Heat Treated Steel, Tool Steel, Titanium Alloys, Nickel Alloys

Speed-Drill X2 Options:

• 3XD or 5XD

• Coolant thru or Non-coolant fed

Applications: Specifically engineered for deep hole drilling in tough materials such as stainless steel, titanium, and nickel alloys. With a 4-facet point and 4 guide lands, it provides stability and precision even in extended drilling depths.

Materials: Stainless Steel, Heat Treated Steel, Tool Steel, Titanium Alloys, Nickel Alloys

Speed-Drill X4 Options:

• 8XD or 12XD

• Coolant thru

Applications: Tailored for non-ferrous metals like aluminum, copper, and bronze. The combination of a 4-facet point with 4 guide lands ensures rapid material removal and a smooth finish in softer metal applications.

Materials: Aluminum, Cast Aluminum, Copper, Bronze

Speed-Drill A4 Options:

• 5XD or 8XD

• Coolant thru

Applications: Developed with a focus on iron-based materials, including gray iron and ductile iron. The special corner radius coupled with the 4-facet point ensures longevity and precision, making it a preferred choice for casting and forging applications.

Materials: Gray Cast Iron, Ductile Iron, Compacted Graphite Iron (CGI), Forged Steel

Speed-Drill R4 Options:

• 3XD or 5XD

• Coolant thru

Applications: When the demand is for ultra-precise bores and clean hole exits, the Speed Dreamer steps up. Its 6 guide lands make it the go-to choice for high-tolerance applications in various steel and cast iron materials.

Materials: Gray Cast Iron, Ductile Iron, Cast Steel, Alloyed Steel, Unalloyed Steel

Speed Dreamer Options:

• 3XD or 5XD

• Coolant thru

Applications: The Rambo is the powerhouse of our drill selection, designed to tackle short chipping materials with ease. Its 4-flute geometry enables rapid material removal for even the most challenging materials, making it an invaluable drilling tool for high-speed operations where efficiency is key.

Materials: Gray Cast Iron, Ductile Iron, Cast Steel

Rambo Options:

• ∅6.00mm – 20.00mm

• 4XD or 6XD

• Coolant thru or Non-coolant fed

DOWNLOADS & ADDITIONAL RESOURCES

Download your copy of MK Tools – Solid Carbide Drills Catalog today!

DOWNLOADS & ADDITIONAL RESOURCES

Download your copy of MK Tools – Solid Carbide Drills Catalog today!

DOWNLOADS & ADDITIONAL RESOURCES

Download your copy of MK Tools – Solid Carbide Drills Catalog today!