HIGH QUALITY SOLID CARBIDE

TOOLING FOR PRECISION RESULTS

HIGH QUALITY SOLID CARBIDE

TOOLING FOR PRECISION RESULTS

Thanks to the partnership of MK Tools and Monaghan Tooling Group, manufacturers and OEMs now have access to the most cost-effective and time-saving solid carbide tooling solutions for countless applications. Whether you’re looking for solid carbide drills or solid carbide endmills, Monaghan Tooling Group empowers your company as a reliable partner in high performance tooling.

Innovative designs and the latest generation of CNC grinding machines ensure that MK Tools’ standard and solid carbide tools meet your tooling requirements. These quality solid carbide components are engineered to achieve the highest performance and quality possible.

Additionally, MK Tools has in-house coating capabilities to help reduce lead time on your orders.

If you would like to learn more about MK Tools or have an application that would be a good fit, contact us here.

SOLID CARBIDE TOOLING APPLICATION EXAMPLES

Here are a few successful applications utilizing MK Tools solid carbide drills.

Connecting Rod

Connecting rod drilled with MK Tools Solid Carbide Drill.

- Material: C70, Steel.

- Tooling: Drills with S4 geometry (coated) spotfacing tools, Z=6 (coated).

- Advantages: Approx. 3000 holes (drilling).

Injection Pump

Injection pump drilled with MK Tool’s solid carbide drill.

- Material: 42CrMoV4, steel.

- Tooling: Special drilling tool with S2 geometry.

- Advantages: Extended tool life and process stability.

Wheel Carrier

Wheel carrier machined with MK Tool’s solid carbide drill.

- Material: 9SMn28K, Forged Steel.

- Tooling: Special geometry for the reduction of cutting force.

- Advantages: Special geometry prevented part movement.

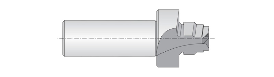

Guide Wheel Shaft

Guide wheel shaft machined with solid carbide drill.

- Material: Forged steel, case hardened (>=670 HVS).

- Tooling: Special hard-drilling tool, solid carbide step drill, hardened geometry.

- Advantages: Cycle time reductions and maintained hole size.

MK TOOLS FEATURES

- Tool geometries for highest cutting data and the longest tool life.

- Cutting tools for the most frequently encountered materials – ferrous & non-ferrous.

- Made with the newest premium carbide grades.

- Advanced coatings specified to best suit the application.

- Exclusive production on ultra-modern CNC grinding centers.

- Rapid and reliable delivery dates.

- Outstanding cost/performance ratio.

- Decades of professional experience.

- Recorded data for quality assurance.

MK TOOLS FEATURES

- Tool geometries for highest cutting data and the longest tool life.

- Cutting tools for the most frequently encountered materials – ferrous & non-ferrous.

- Made with the newest premium carbide grades.

- Advanced coatings specified to best suit the application.

- Exclusive production on ultra-modern CNC grinding centers.

- Rapid and reliable delivery dates.

- Outstanding cost/performance ratio.

- Decades of professional experience.

- Recorded data for quality assurance.

Special Solid

Carbide Tooling

Decades of experience in the most demanding applications means machine shops get excellent application-specific tooling from MK Tools. They offer individual solutions to challenging applications with rapid and reliable lead times. If you want to discuss an application with us, contact us here!

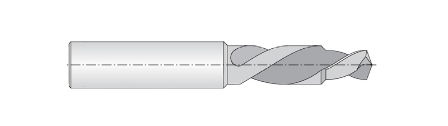

Step Drills

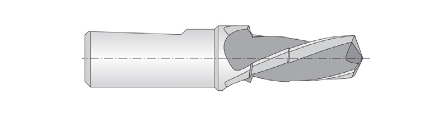

Core drills

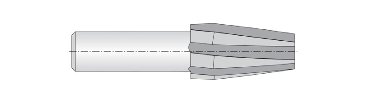

Tapered drills & Reamers

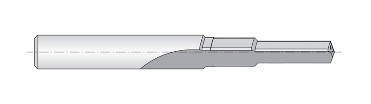

Reamers & Step Reamers

Milling tools

Combination tools (Drilling / Milling)

Applications & Case Studies

CASE STUDY

Rambo Drill Cycle Time Reduction

A manufacturer was machining 2 pin bores on a high volume automotive part made out of ductile iron.