THE CHALLENGE

One of our customers was manufacturing electrical motion control components using a 4-spindle CNC Lathe in high volume. The parts were made of 1215 steel with an aluminum-bronze weld. This particular blind bore required a surface finish of 32 Ra microinch (.8 Ra).

OUR SOLUTION

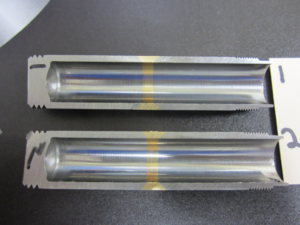

When the customer contacted us, we recommended our Diatool 3252, standard monoblock reamer with Cermet blades and a unique geometry to achieve a very good surface finish without the need for a secondary operation. The reamer has (6) cutting blades and features coolant through the center of the tool.

- RPM = 4,000

- Feed rate = 0.02” per revolution

- Cutting speed = 80 inches per minute

- Finish achieved: 3-4 Ra microinch (0.08-0.1 Ra)

- Tool life: 8,000 parts