Summary Of Results

- Tool Life Improvement: 30 pieces to 1,000 pieces per tool

- Tool Reduction: 200 to 6 annually

- A secure and consistent process was established

THE CHALLENGE

A manufacturer was machining 6,000 medical tubes per year. The tubes were made of 1.4301 stainless steel. Previously the manufacturer was only achieving 30 pieces per tool and using 200 reamers a year. The Monaghan and Diatool teams were contacted to help improve tool life.

- Diameter and Tolerance: 15mm ±0.004

- Bore length: 160mm

- Material: 1.4301 Stainless Steel

- Surface quality: max Ra 0.8 (no visible marks allowed)

- Machine: Okuma Lathe

The Previous Solution:

- Tool: modular disk reamer

- Tool Life: 30 pieces

- Description of Tool: Solid carbide coated

OUR SOLUTION

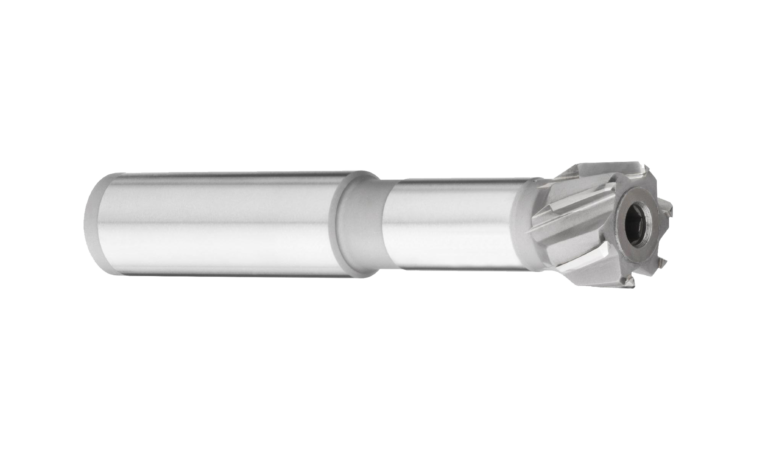

When the customer contacted us, we recommended a special Diatool monoblock reamer with a clamping flat. The reamer is solid, ATC coated, special b-length 180mm, with chip breaker G1403A-SB-KR. The reamer has 4 cutting blades and features coolant through the center of the tool.

- Tool: Diatool special mono block reamer, with clamping flat

- Machining Time: 34.3 seconds

- Tool Life: 1,000 Pieces

FINAL RESULTS

After working with the Monaghan and Diatool teams the manufacturer was able to reduce the number of tools needed from 200 to 6. The manufacturer was able to take advantage of Diatool’s reamer re-tipping and only needed 2 reamers and 4 re-tips for annual production! The new process is secure and consistent.

- Tool Life Improvement: 30 pieces to 1,000 pieces per tool

- Tool Reduction: 200 to 6 annually

- A secure and consistent process was established