SUMMARY OF RESULTS

- Tool Life Improvement: 150 pcs to 9800 pcs

- Machining Time Reduction: 14.29 seconds to .70 seconds

- Cost Per Piece Reduction: $0.13 to $0.034

- Item Savings: 60% reduction in tooling costs

- Annual Savings: $11,125

THE CHALLENGE

A manufacturer was machining a 41.25mm diameter bore on a cylinder mount. The Monaghan & Diatool team were contacted to help reduce machining time an increase tool life.

- Diameter and Tolerance: 41.25mm (+/- .025)

- Bore length: 25.40mm

- Material: ASTM A36 HRS

- Surface quality: Ra 3.2

- Machine: Makino A51 – Horizontal Mill

The Previous Solution:

- Tool: Bore, Inserted Cartridge

- Tool Life: 150 pieces

- Description of Tool: Triangle Insert TOHX 06T102 L-G06

- Number of teeth: 1 effective, 3 total

- Machining Time: 14.29 seconds

- Cost per pcs.: $0.13

OUR SOLUTION

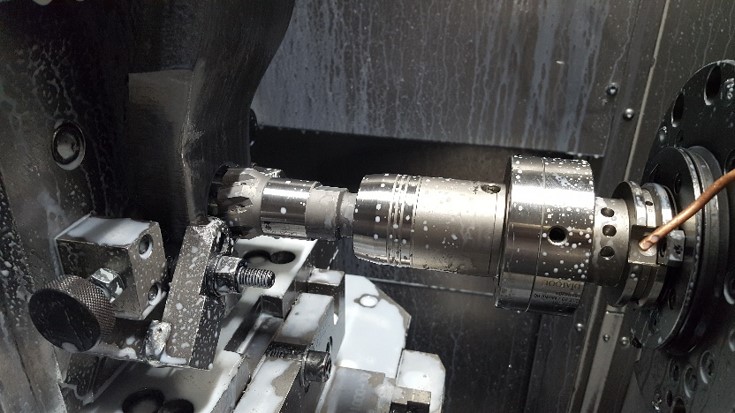

When the customer contacted us, we recommended a standard Diatool monoblock reamer. The reamer is solid, Cermet tipped with 8 cutting teeth.

- Tool: Diatool Standard Monoblock Reamer

- Description of Tool: Solid, LH Helix/RH Cut, Cermet tipped

- Number of teeth: 8 effective

- Machining Time: 0.70 seconds

- Tool Life: 9,800 Pieces

FINAL RESULTS

After working with the Monaghan and Diatool teams, the manufacturer was able to increase productivity by 95%. They also experienced a 60% reduction in tooling costs and realized annual savings of $11,125.

- Tool Life Improvement: 150 pcs to 9800 pcs

- Machining Time Reduction: 14.29 seconds to .70 seconds

- Cost Per Piece Reduction: $0.13 to $0.034

- Item Savings: 60% reduction in tooling costs

- Annual Savings: $11,125

Our team has worked with thousands of different applications. If you have a question or are wondering if your application is a good fit for a Diatool reamer, contact us here. We’re happy to discuss your options for CNC reaming or reamers!