Gearbox Drive Shaft – Case Study

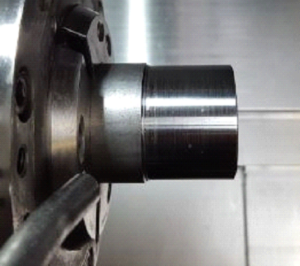

Gearbox Drive Shaft Case Study The Challenge A customer of ours was manufacturing gearbox drive shafts using a Mori Seiki CNC Lathe. The shafts required

Gearbox Drive Shaft Case Study The Challenge A customer of ours was manufacturing gearbox drive shafts using a Mori Seiki CNC Lathe. The shafts required

Master Cylinder Piston – Case Study The Challenge A customer of ours was manufacturing master cylinder pistons made of 3415 case hardening steel using a

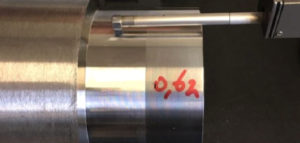

The Challenge This customer was manufacturing a shaft used in the oil industry made of Super Duplex stainless steel using a DMG Mori NTX2000 machine.

Get the latest news, offers, and machining resources from your hole finishing experts by signing up for the Monaghan Tooling Group mailing list:

30 N. Clinton Street

Dayton, Ohio 45402

Toll-Free: 1.800.732.4565

Phone: 937.253.7706

Fax: 937.723.7702

Material: Ductile Iron

Tooling: Rambo Speed Drill with GTX Coating

Advantages:

Material: C70, Steel

Tooling: Drills with S4 geometry (coated) Spotfacing tools, Z=6 (coated)

Advantages: Approx. 3000 holes (drilling)

Material: 42CrMoV4, Steel

Tooling: Special drilling tool with S2 geometry

Advantages: Extended tool life and process stability