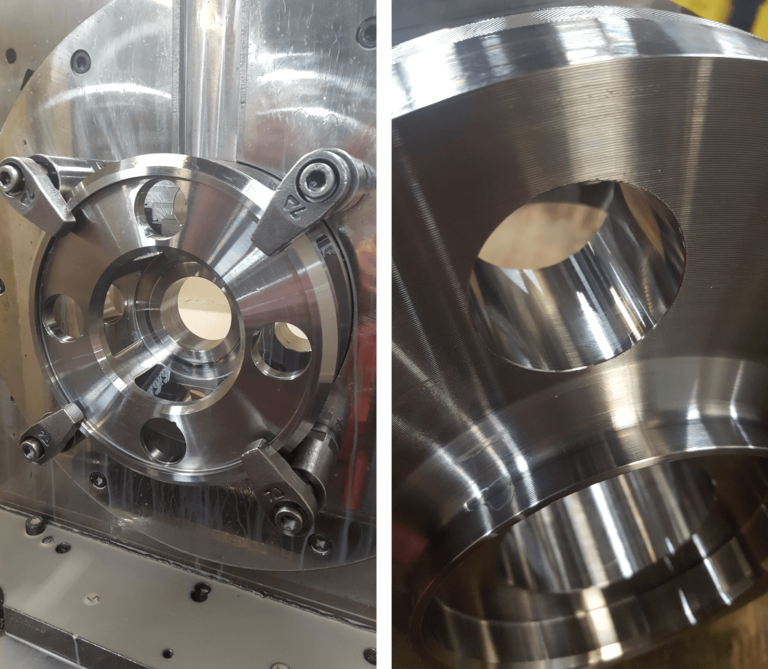

Diatool Reaming Carrier

The Challenge

A competitor’s reamer was not consistent for tool life and results were unpredictable. A Monaghan Technical Account Manager was contacted to help provide a better solution than the current reamer. A Diatool reamer was installed with chip breaking geometry and produced a good part on the first hole. The chip breaker was added to remove stringy chips and yield a predictable process.

- Material: 4142 PH

- Feature: 1.5542″ -1.5552″

- Length: 2.125″

- Bore: Through

- Ra max: 75

- Vc: 105 m/min (344 sfm)

- Fz: 0.12 mm/per (.0047″) Stock

- Allow: 0.30 mm (.0127″)

Our Solution

- Reamer: Diatool – MDHR000984

- Type: 3451

- Blade: Cermet 24 – 8X

- Coating: None

Final Results

The size is running to the mean of the tolerance and yielding a Ra of 14 on the finish and because of the chip breaker there are no longer problems with chips wrapping around the part. This is beneficial because chips can affect surface finish or cause problems with tool changes.

- Bore Size: 1.5548″ Ra

- Achieved: 14

- Pre-bore: 1.542″

Additional Information:

- Holder: Cat 50 x Mod 80 Compensation

- Chuck: Mod 80 x 25mm Hydraulic

- Machine: Mazak Nexus 6800-II

- Spindle: Cat 50 Coolant: Water Soluble