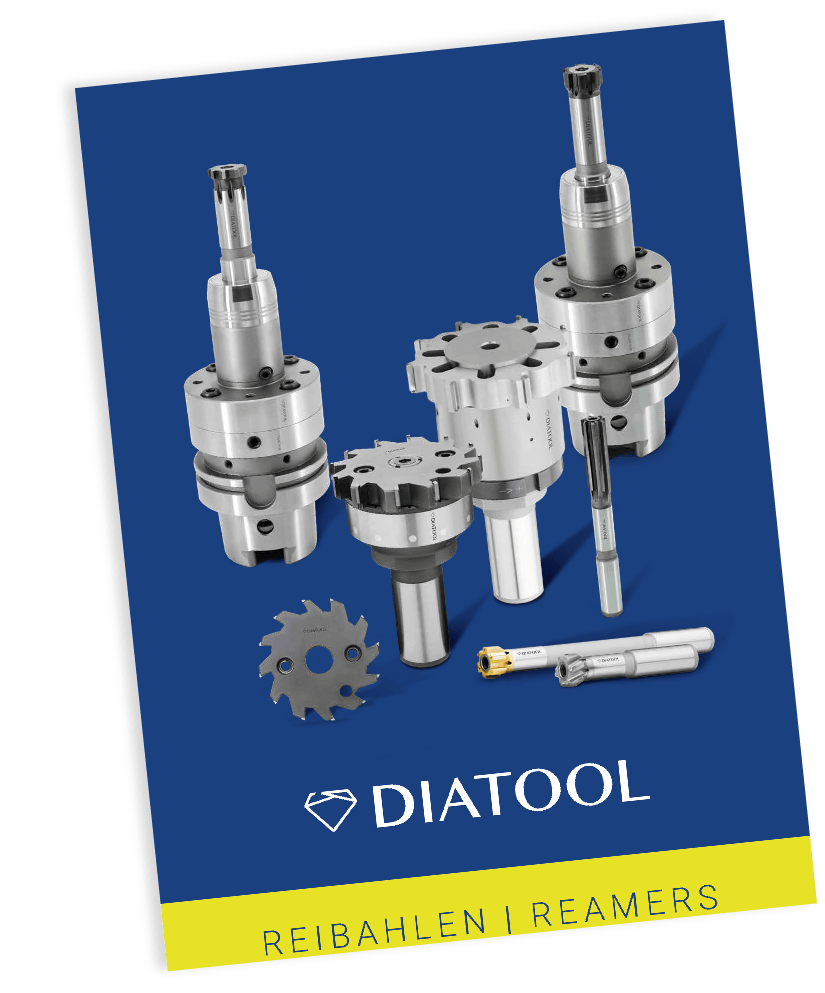

DIATOOL REAMER

RECONDITIONING

Benefits Of Reamer Reconditioning

Diatool’s reamer reconditioning saves money and ensures reliability for high-volume or precision production. Re-tipping tools reduces waste and supports sustainability.

Benefits include:

- Lower cost vs. buying new tools

- Same tool life & quality as new tools

- Tools can be re-tipped an UNLIMITED amount of times

- Competing brands can be re-tipped

Ask us about our emergency services for critical deliveries. Send your tools to us and we take care of the rest! It’s that easy.

Contact our team to see if your reamer is eligible to be re-tipped!

Simple. Fast. Precise.

Diatool re-tips reamers to “as good as new” at half the cost of a new tool, with no limits on re-tipping. We recondition monoblock reamers, cutting rings, and modular reamers from most competitors in various styles and materials like CERMET, Carbide, or PCD, with advanced coating options available.

Have questions about Diatool reamer re-tipping?

Contact our team here!

TAKE A LOOK INSIDE DIATOOL

Diatool’s state-of-the-art reconditioning facility is equipped with CNC grinding machines, laser measurement systems, and advanced coating chambers to ensure precision and performance. Our experienced engineers specialize in restoring tools for industries such as automotive, aerospace, and heavy equipment manufacturing, where even the smallest deviations in reamer dimensions can result in production inefficiencies.