When working with the aviation industry, precision and excellent quality are demanded from the tools supplied to these manufacturers. Strict guidelines and regulations must be met in most machining applications but even more so in aerospace applications. The slightest inaccuracies will result in scrapped parts and ultimately lost time and money.

To avoid such precious losses, aerospace manufacturers need precision tooling coupled with excellent support in order to be efficient in producing parts. High-performance reaming tools from Diatool are successful in holding size and meeting surface finish requirements in some of the most demanding applications.

High-performance reamers have a very stable design with multiple cutting teeth that allow them to produce excellent bore quality and run at faster speeds. In the aviation industry manufacturing using multiple different types of materials is very

common. Some of these materials are very expensive and manufacturers cannot afford to scrap parts. With high performance reaming, you are working with a precision tool that does not require a diameter setting.

High-performance reaming tools are a plug and play solution compared to single point boring. Thanks to their precision, these reamers can greatly reduce the amount of scrapped parts. The reduction of scrapped parts and the efficiency of these reamers will not only provide the precision needed to meet aviation standards but will also reduce costs along the way.

Different types of applications and materials require different types of reamers. Fortunately, Monaghan Tooling Group offers Diatool’s complete line of high-performance reamers.

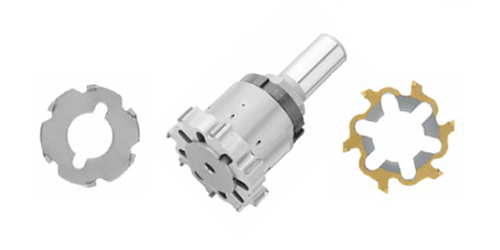

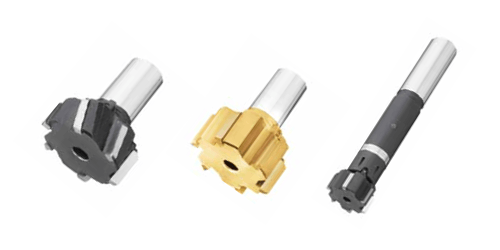

Some of these high-performance reamers include solid and expandable monoblock reamers which are very stable thanks to the monoblock design. Reaming head style reamers which are all ground to the nominal size meaning the first bore will be a good bore. Cutting ring style reamers and the top speed ring. Diatool reamers can also be coated to increase tool life and bore quality.

All of the reamers listed above will provide the precision that is required of the aviation industry. Contact us today to learn more about how our high-performance reaming tools will help your aviation business.