Vergnano Precision Tooling:

Precision Solutions for Threading

Vergnano Precision Tooling:

Precision Solutions for Threading

Vergnano: A Partner in Innovation

Monaghan Tooling Group brings you a new partner in innovation. Vergnano has been a force in the machine tooling market for nearly eighty years, providing high-precision threading tools. Vergnano’s innovative and dynamic spirit matches their renowned professionalism and expertise.

Contact Monaghan Tooling Group to learn more about Vergnano CNC tools.

Precision Threading for The US Market

Monaghan is the US partner of Vergnano, a leader in tapping tools, solid-carbide hobs, and thread mill manufacturing. Innovation in threading tools is a committment at Vergnano. We’re dedicated to elevating your manufacturing process with the best threading tools.

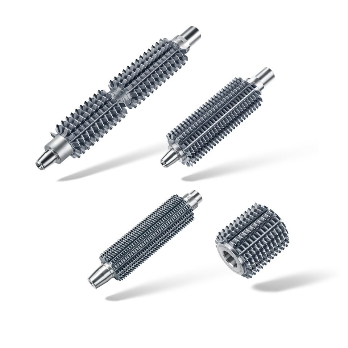

Vergnano’s Product Overview

Explore Vergnano’s premium range taps, hobs and thread mills, designed for high performance and precision for the machine shop professional. Each tool embodies our shared dedication to quality and efficiency in manufacturing.

Get More Than A Tool

We promise not just tools, but solutions. Vergnano’s products, backed by cutting-edge technology and rigorous quality standards, ensure superior performance and longevity. Explore their product range below, and find solutions to your threading challenges.

TECHNICAL REFERENCES,

DOWNLOADS & ADDITIONAL RESOURCES

Download the Vergnano Full Catalog