SUMMARY OF RESULTS

- Productivity Gain: 1000%

- Machining Time Reduction: 270 seconds to 27 seconds

- Yearly Cost Savings: $29,160

- 2.3 Months ROI

THE CHALLENGE

A manufacturer was interpolating to machine internal grooves on a part made out of cast aluminum. With their current process, cycle time was 270 seconds per part. The goal was to reduce cycle time utilizing the Internal Recessing Unit (IRU).

- Scope: Reduce cycle time

- Material: Cast Aluminum

- Batch Size: 800 Pieces

- Machine: Horizontal Mill, Cat 40, TSC

The Previous Solution:

- Interpolation

- Cycle Time: 270 seconds

OUR SOLUTION

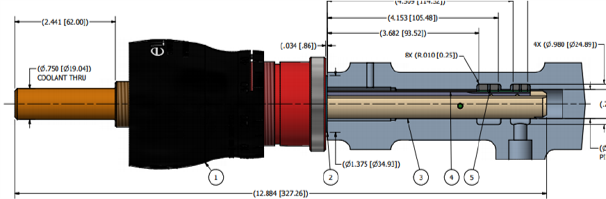

We recommended the Internal Recessing Unit (IRU), manufactured by Elliott Tool Technologies. The IRU is designed specifically for the application to machine each internal groove at once.

- Tool: Internal Recessing Unit (IRU)

- Cycle Time: 27 seconds

FINAL RESULTS

After working with the Monaghan and Elliott team the manufacturer was able to drastically reduce cycle time from 270 seconds to 27 seconds per part. This resulted in a yearly cost savings of $29,160.

- Productivity Gain: 1000%

- Machining Time Reduction: 270 seconds to 27 seconds

- Yearly Cost Savings: $29,160

- 2.3 Months ROI