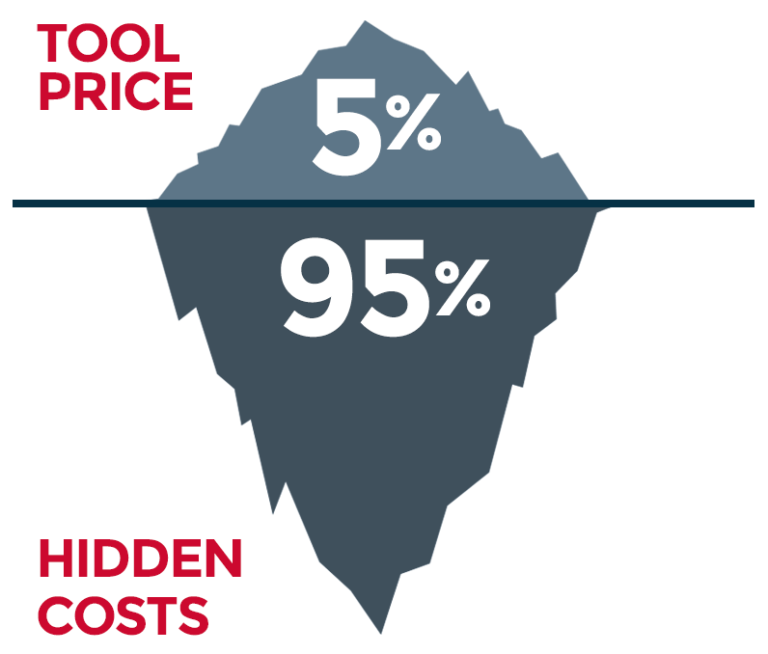

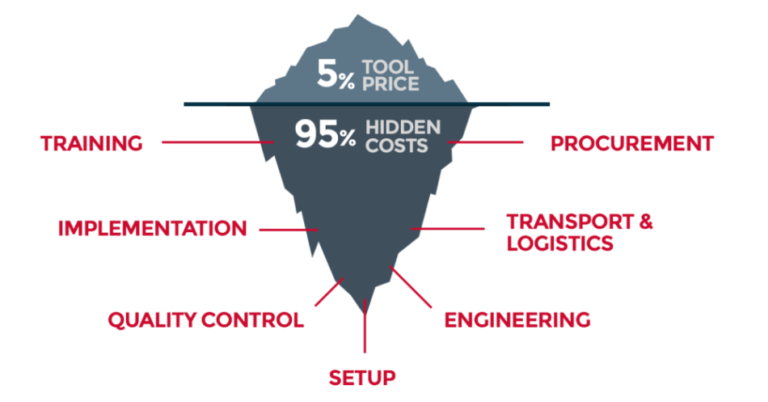

THE ICEBERG PRINCIPLE

ON AVERAGE, TOOLS MAKE UP ONLY AROUND 5% OF THE TOTAL COST OF A JOB.

The remaining 95% of the cost comes from…

Internal time and resources

Overhead

Expenses

Opportunity cost

These can exist under such headings:

Buying

Inventory

Logistics

Packaging

Customization

Quality control

Implementation

Switching costs

Training

Support

Ongoing licenses

Maintenance

Energy and other operating costs

This chain of events adds costs to the entire hole finishing ecosystem.

Experience in the tooling industry has shown that cost savings of 50% and more can be achieved in the areas of logistics and engineering alone. This has a lasting effect on the total costs of the end product.

As an example, our Diatool high performance reamers are engineered to your application, exhibited by their quality, precision, faster cutting data and long tool life.

Testing with these reamers has shown that tool life alone will drastically lower the total cost of ownership by the sheer number of tools required to do a job and the associated setup costs.

To ensure that costs of inventory, carrying and logistics are kept to a minimum, Diatool reamers are delivered in short lead times (3-4 weeks) with a reliable supply chain and top notch customer service through Monaghan Tooling Group.

Additionally, all Diatool reamers can be re-tipped a minimum of 10X, at 2/3 the cost of new. Expandable reamers compensate for wear and can extend tool life even further.

While other solutions often introduce additional heavy costs in machinery, manpower, consumables and setup, Diatool reamers answer the call to minimize the “95% hidden costs of the iceberg”.

Monaghan Tooling Group continues to demonstrate our ability to offer you superior solutions to help outperform the competition by minimizing your hidden costs of ownership.