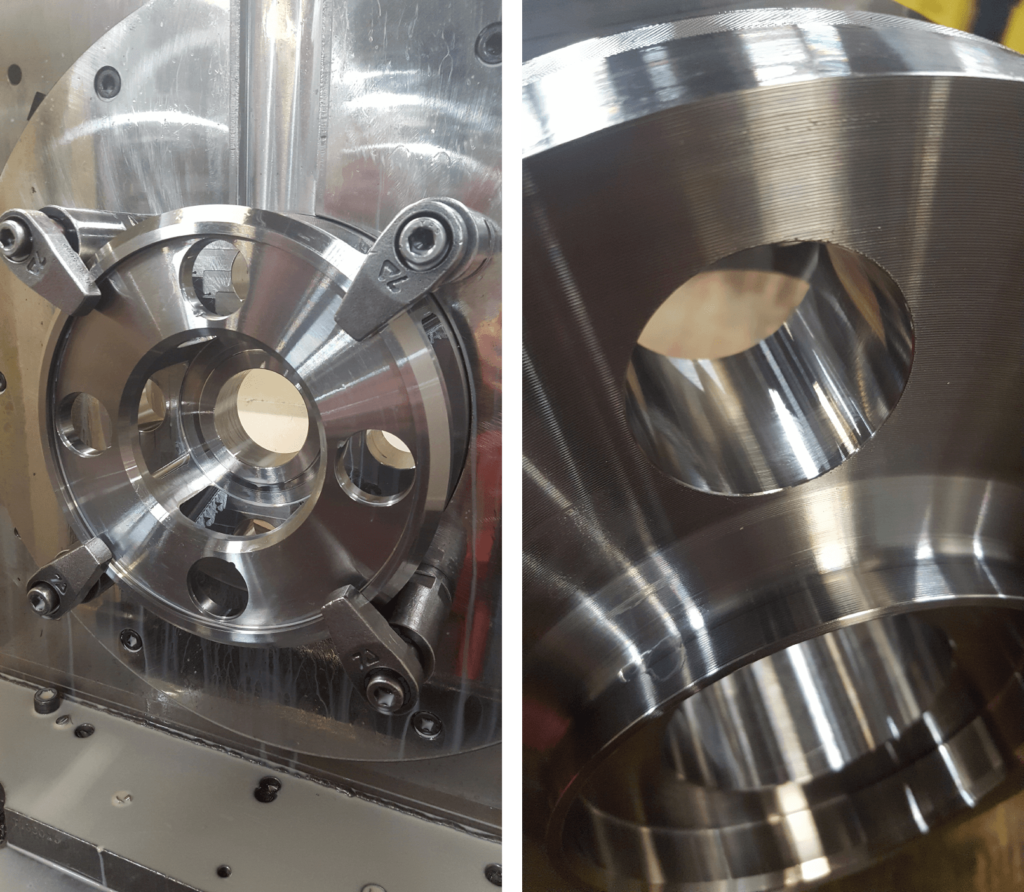

Empowering Production with High Performance Tooling Solutions

Unsurpassed Industry Expertise

We live metal cutting every day. We know the trends of what’s working, so you don’t have to.

5 Issues That Drive Manufacturing Engineers Crazy

Os jogadores de cassino MostBet atraem taxas mínimas, várias opções de reabastecimento e saída de dinheiro, programa de bônus generoso e muitos outros benefícios.

High Scrap

Rate

High

CPU

Process Security

Low

Skill Set

Machine Downtime

Vantagens de Jogar em Casinos Online com Skrill em 2024

Utilizar a Skrill como método de pagamento em online casinos que aceitam skrill oferece uma experiência de jogo incomparável em 2024. Com a Skrill, pode fazer depósitos e levantamentos de forma rápida e segura, graças à funcionalidade 1-Tap, que permite transações instantâneas com um único clique. A segurança é uma prioridade, com sistemas de encriptação avançados que protegem as suas informações financeiras, garantindo que pode jogar com tranquilidade. Além disso, muitos casinos que aceitam Skrill oferecem bónus exclusivose promoções especiais para os seus utilizadores, proporcionando ainda mais valor às suas apostas. O programa VIP da Skrill é outro benefício importante, oferecendo comissões mais baixas, suporte ao cliente prioritário e recompensas adicionais que tornam a experiência de jogo ainda mais vantajosa. Se procura uma maneira eficiente e segura de gerenciar as suas transações em casinos online, a Skrill é a escolha ideal para 2024. Jogar em casinos que aceitam Skrill não só simplifica o processo de pagamento, mas também garante que você aproveite ao máximo

Innovative Solution Process

6 Key Steps To Finding Your Solution

Precision Hole Finishing can present significant challenges to manufacturers in high performance machining facilities.

Value Driven Solutions

ROI on Monaghan Tooling Solutions are normally achieved in 3 months or less!

Satisfied Customers

A FEW OF OUR LOYAL CUSTOMERS