High-Performance Reamers

for Precision Machining

Multi-Blade Reamers for

Superior Quality Precision Bores, Process Stability and Cost Savings

Diatool high-performance reamers produce precise bores at faster speeds and feed rates compared to conventional reamers and single-point boring tools. These reamers have a multi-blade design with unequally spaced cutting edges, ensuring precision, speed, quality, process security, and low cost per part.

REAMING OPTIONS

Monoblock Reamer Types

Monoblock versions are available in expandable and solid (non-expandable) styles for producing high-quality bores. Compensation for wear can be made by tightening a conical screw in the expandable monoblock-style reamer.

Solid and expandable Ø5.600mm – 60.599mm (upon request up to Ø100.599mm)

View Products

Solid and expandable Ø5.600mm – 60.599mm (upon request up to Ø100.599mm)

Reaming Heads

Rapid-set reaming heads are available as a non-expandable, modular option. Reaming heads are interchangeable with the major European brands.

Modular reaming heads: Ø9.600mm – 60.000mm

View Products

Modular reaming heads: Ø9.600mm – 60.000mm

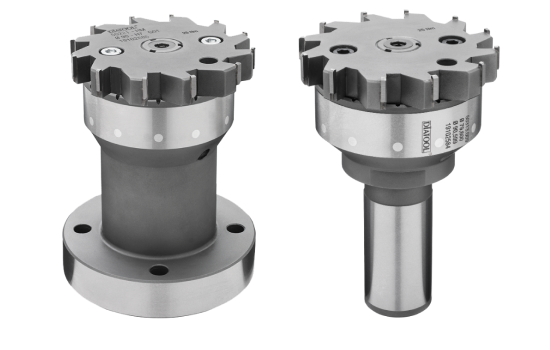

Top-Speed Ring Reamer Types (TSR)

The Top-Speed Ring (TSR) is a solid modular reaming system with up to 16 cutting teeth, depending on size. The TSR is easy to assemble and can run at much faster feed rates.

Diameter range: 50.000mm – 225.000mm (1.19921” – 8.8583”)

View Products

Diameter range: 50.000mm – 225.000mm (1.19921” – 8.8583”)

Expandable Cutting-Ring Reamer Types

Cutting rings offer an expandable modular design for larger hole diameters and are interchangeable with major European brands. Compensation for wear is made by turning an expansion nut on the mounting arbor. DIATOOL also offers a unique solid (non-expandable) cutting ring when expansion is unnecessary (also with a left-hand helix option).

Modular cutting rings Ø50.600mm – 150.599mm)

View Products

Modular cutting rings Ø50.600mm – 150.599mm)

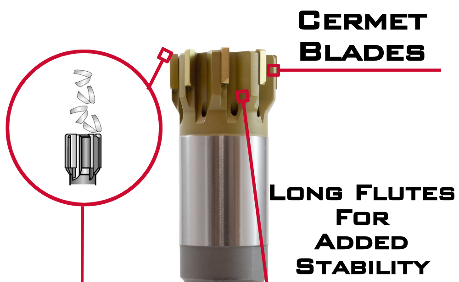

Top-Speed Disc

The Top Speed Disc uses solid disks made of cermet or solid carbide, allowing for higher feed rates. It also has the flexibility of a steel body with enhanced cutting disks for superior performance.

Size range: Ø16.00mm – 32.00 mm

Size range: Ø16.00mm – 32.00 mm

Special Tools for Reaming

Special high-performance tools can be designed specifically for your application parameters. Some options include step tools, special lengths, special shank diameters, and tapered reamer tools.

Special Reamers Size Range: Ø 5.900mm – 225.000mm

Special Reamers Size Range: Ø 5.900mm – 225.000mm

Applications & Case Studies

CASE STUDY

Reaming Replaces Boring for Gear Box Production

High-volume production of agriculture machine gear box housings, requiring Ø89.97mm (+/-.018) bore in ductile iron, faced significant quality control challenges.

CASE STUDY

Application Spotlight – Reaming Yokes

Diatool’s expertise in the production and development of high-performance reamer tools has led them to create multiple innovative solutions for reaming slip yokes.

CASE STUDY

Reaming Replaces Boring

Replace single point boring with a more stable process machining a railroad tie puller part. The goal was to increase tool life and hold size without the need for operator adjustment.