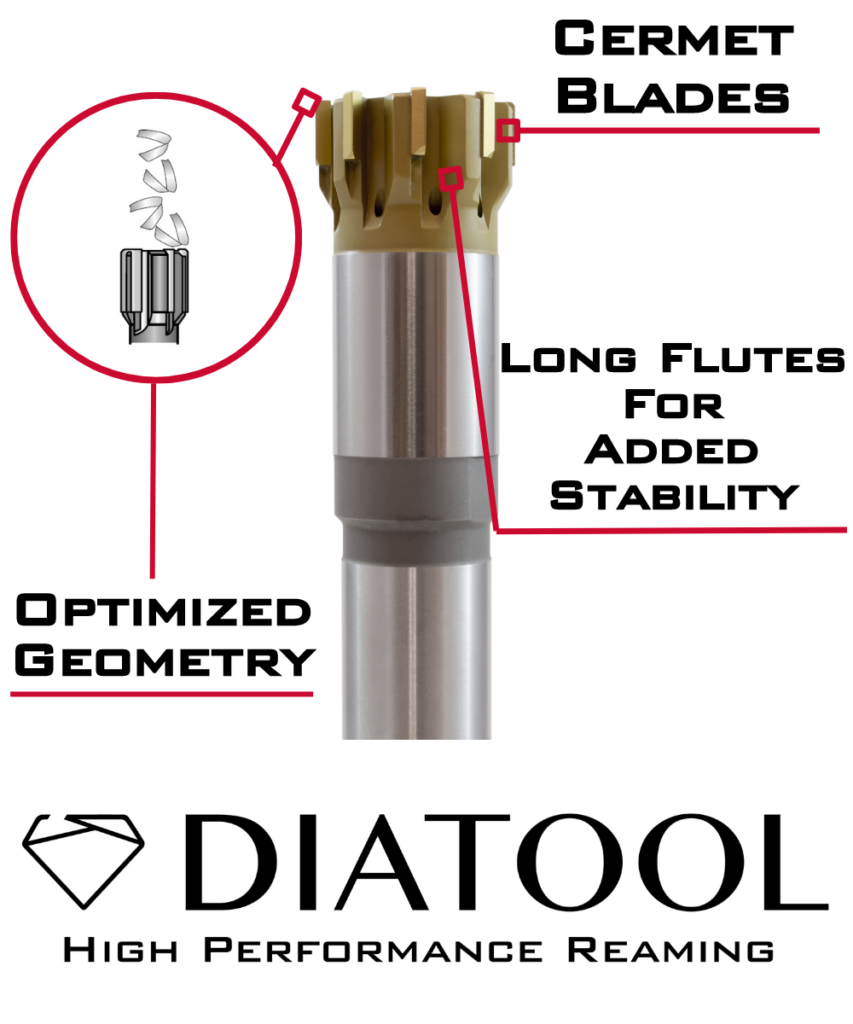

Diatool High Performance Reaming

Multi-blade Reamers for Superior Quality Bores, Process Stability & Cost Savings

DIATOOL’s high performance reaming products produce precision bores at much higher feed rates than single-point tools – reducing cycle time and total cost of ownership.

DIATOOL’s high performance expandable reaming products offer a multi-blade design with unequal spacing of the cutting edges. This produces very round and cylindrical bores compared to conventional reamers and at much higher feed rates than single-point tools.

We are also able to offer DIATOOL’s quick turnaround reconditioning to customers with competitor’s products. This is a huge advantage for those not wishing to waste their initial investment but are not able to afford the long lead times they are experiencing from DIATOOL’s competitors.

REAMING OPTIONS

Learn More

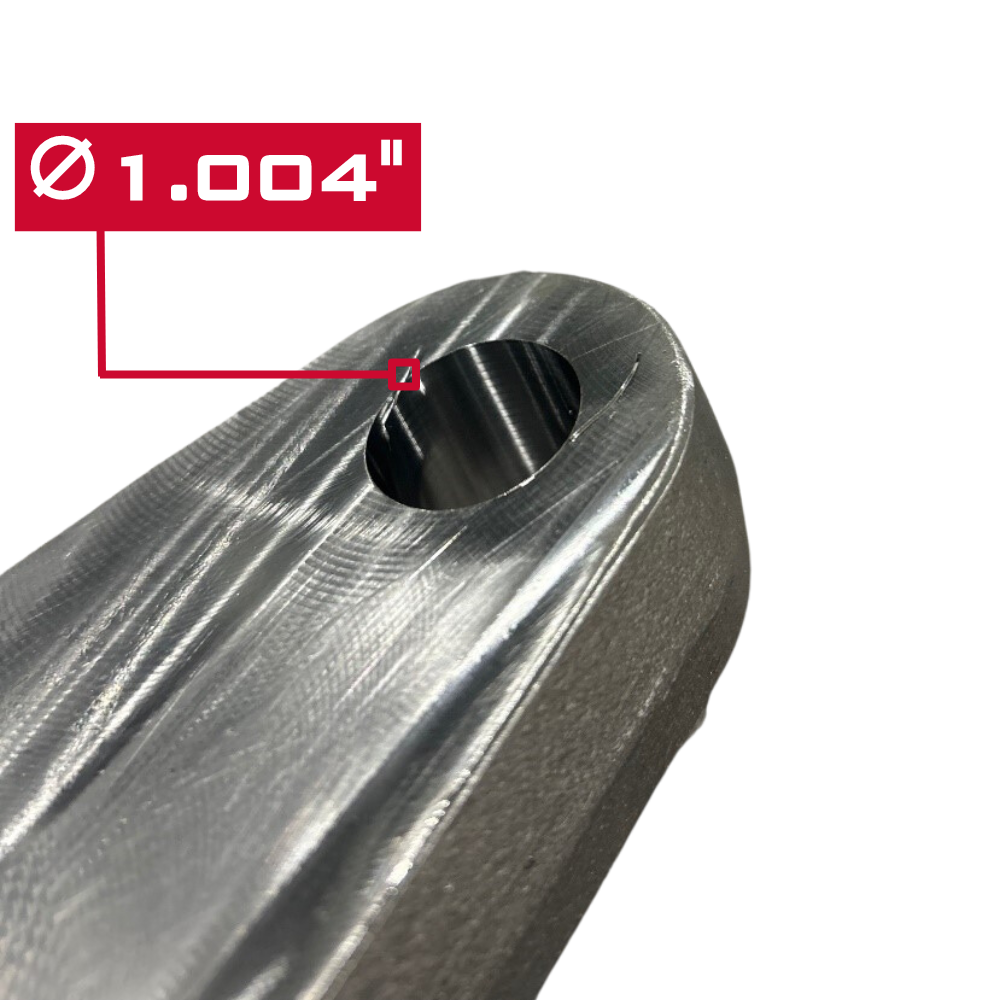

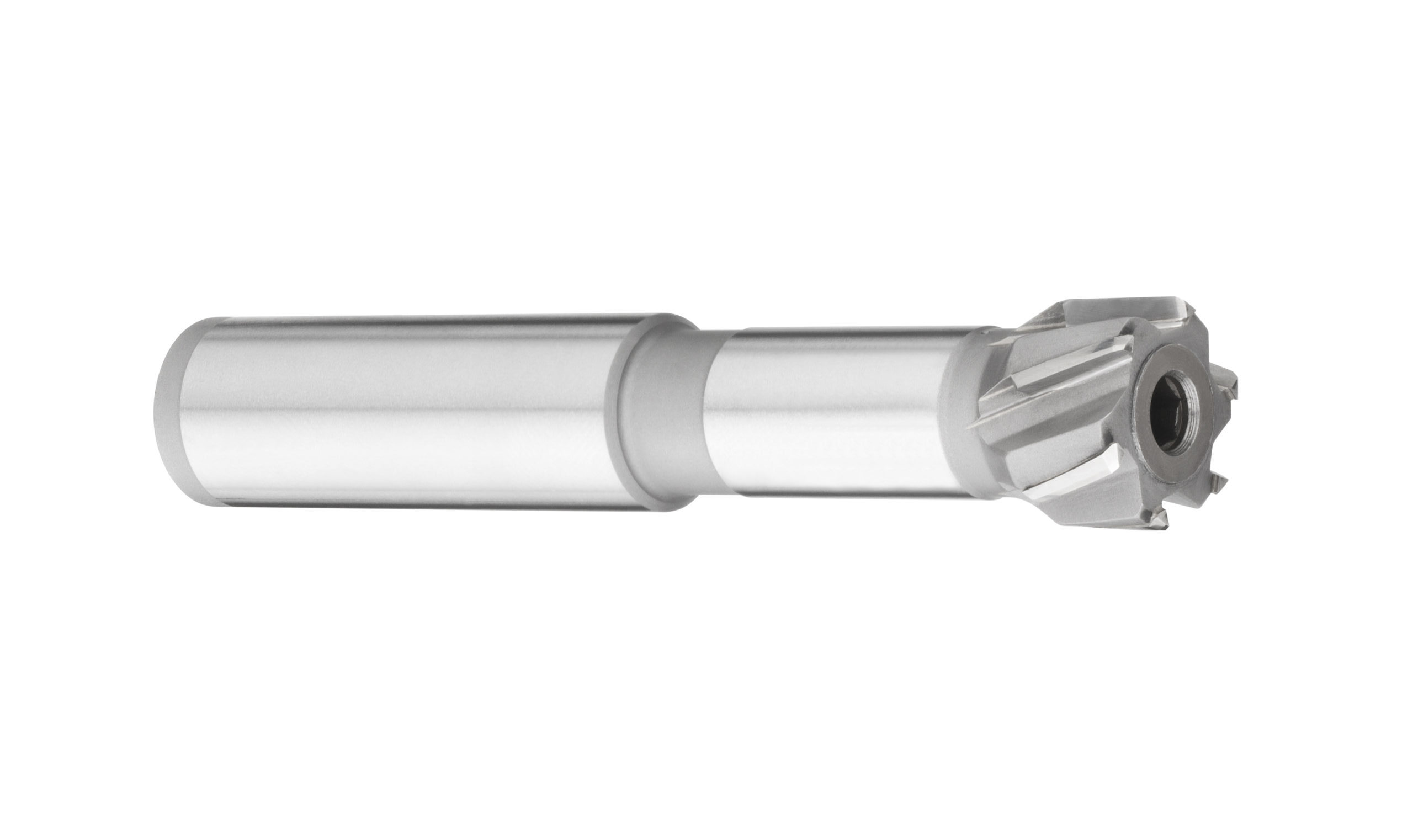

Monoblock reamers are available in both expandable and solid (non-expandable) styles for producing high quality bores. Compensation for wear can be made by tightening a conical screw in the expandable monoblock style reamers.

Solid and expandable Ø 5.600 – 60.599 mm (on request up to Ø 100.599 mm)

Solid and expandable Ø 5.600 – 60.599 mm (on request up to Ø 100.599 mm)

MONOBLOCK REAMERS

Learn More

Cutting rings offer an expandable modular design for larger hole diameters and are interchangeable with major European brands. Compensation for wear is made by turning an expansion nut on the mounting arbor. DIATOOL also offers a unique solid (non-expandable) cutting ring when expansion is not necessary and with the added option of left hand helix.

Modular cutting rings Ø 50.600 – 150.599 mm

Modular cutting rings Ø 50.600 – 150.599 mm

EXPANDABLE CUTTING RING REAMERS

Learn More

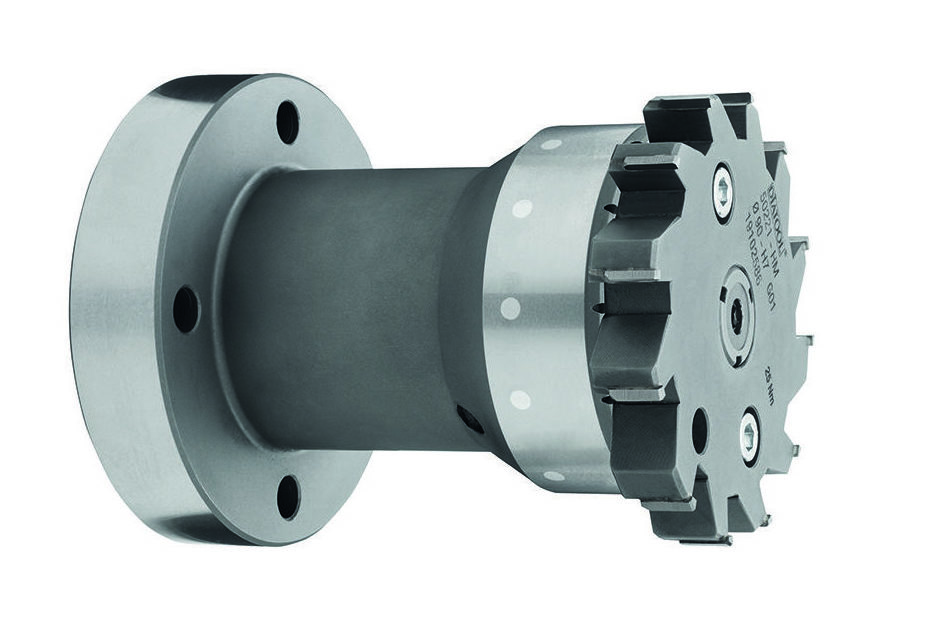

The Diatool Top Speed Ring (TSR) is a newly designed modular reaming system. The TSR provides a multitude of benefits designed to help cut down on tooling costs and improve efficiency.

Diameter Range: 50.000mm – 225.000mm (1.9921”-8.8583”)

Diameter Range: 50.000mm – 225.000mm (1.9921”-8.8583”)

TOP SPEED RING REAMERS (TSR)

Learn More

Rapid-set reaming heads are available as a non-expandable, modular option. Reaming heads are interchangeable with the major European brands.

Modular reaming heads Ø 9.600 – 60.000 mm

Modular reaming heads Ø 9.600 – 60.000 mm