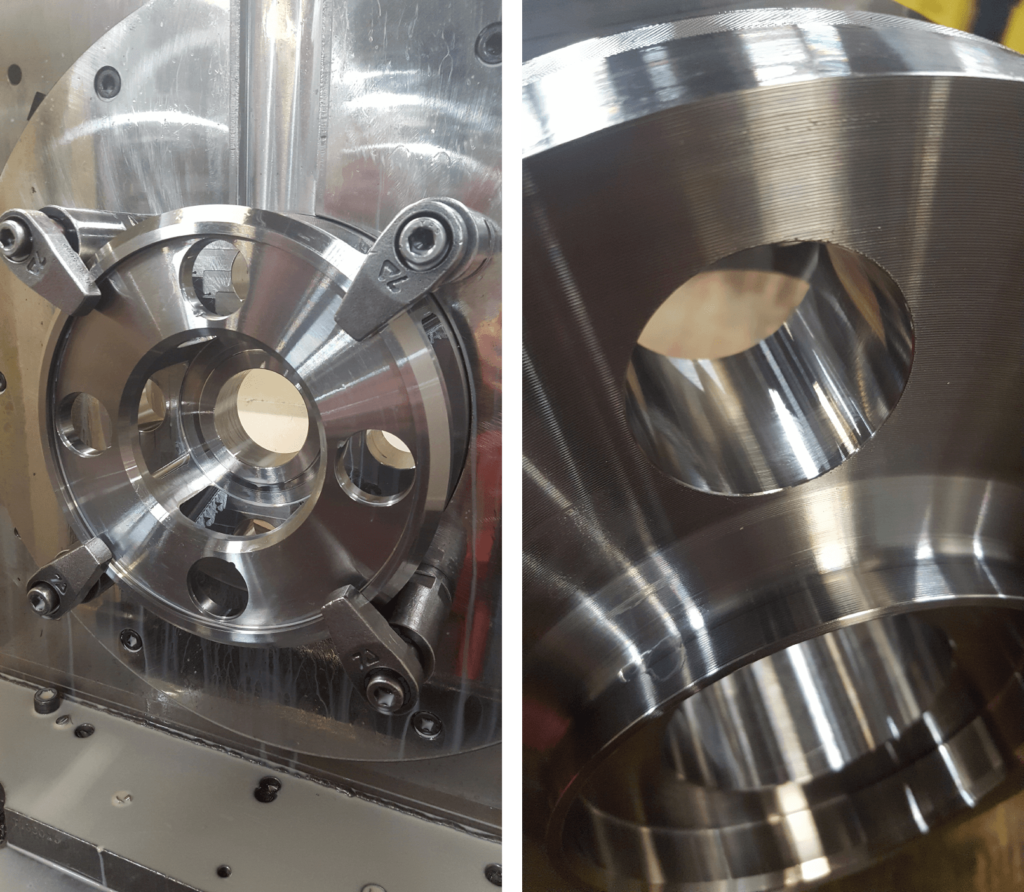

Empowering Precision with High Performance Tooling Solutions

Unsurpassed Industry Expertise

We live metal cutting every day. We know the trends of what’s working, so you don’t have to.

5 Issues That Drive Manufacturing Engineers Crazy

High Scrap

Rate

Due to oversized bores and bad finishes.

High

CPU

Due to long cycle time, expensive tooling and high scrap rate.

Process Security

Low performance in producing parts that meet spec.

Low

Skill Set

Workers have difficulty on complex tooling and lack tuning ability.

Machine Downtime

Revenue production stops when machine is offline for any reason.

Innovative Solution Process

6 Key Steps To Finding Your Solution

Our structured approach combines your experience and our insights together to develop a unique solution that optimizes your process.

Precision Hole Finishing can present significant challenges to manufacturers in high performance machining facilities.

Value Driven Solutions

In today's digital age, finding a reliable and secure payment method for online casinos is paramount for gamers across the globe. With a myriad of options available, it's essential to have a resource that not only explores but also evaluates these methods to ensure a hassle-free gaming experience. For those navigating the digital payment landscape in Austria, one method stands out due to its convenience, security, and user-friendly approach: WebPayz.

By visiting https://gold-chip.at/zahlungsmethoden/webpayz/, you can dive deep into an extensive review of WebPayz, understanding its advantages for online casino transactions. This detailed analysis covers everything from how to set up your WebPayz account, its transaction speeds, to the security measures it employs to protect your financial details.

Ideal for both seasoned players and newcomers to the online gaming scene, this guide is a crucial tool for anyone looking to streamline their payment process in online casinos. It ensures that your focus remains on enjoying your gaming experience, secure in the knowledge that your transactions are swift, straightforward, and, most importantly, safe.

ROI on Monaghan Tooling Solutions are normally achieved in 3 months or less!

Satisfied Customers

"These reamers have given a night and day difference with their chip control. Thanks to all of you for following through and pushing delivery."

We hit our 15-18 value first part with the new data. Thank you very much for the tech support! We could not have done it without you!

A FEW OF OUR LOYAL CUSTOMERS