Precision Mono-Block Reamers -

Solid and Expandable Solutions

Solid And Expandable Mono-Block Reaming

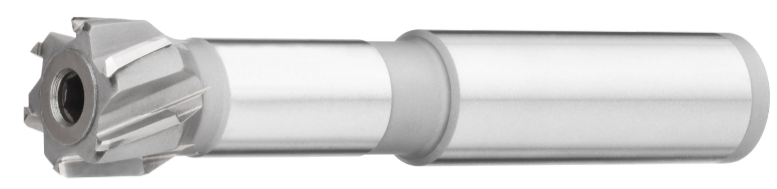

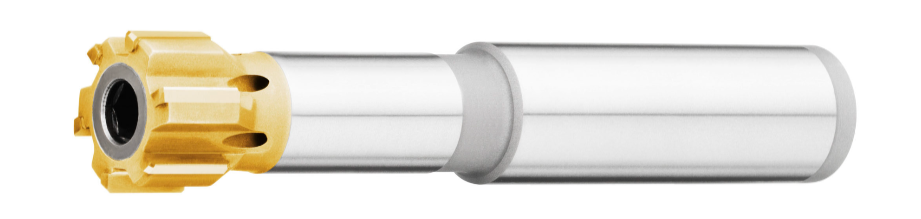

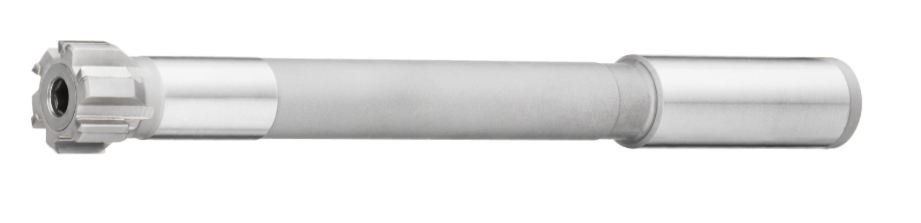

Mono-block reamers are available in both expandable and solid (non-expandable) configuration styles for producing high-quality bores. Compensation for wear can be made by tightening a conical screw in the expandable Mono-block style reamers, while both the solid and expandable styles can be reconditioned for prolonged tool life.

We offer precision mono-block reaming solutions from DIATOOL with options and features including:

- Solid and expandable Ø 5.600 – 60.599 mm

(on request up to Ø 100.599 mm) - With and without internal coolant supply

- Short and long versions

- Options for many different reamer cutting speeds, cutting materials, and coatings

- Wear compensation through an easy-to-use expansion feature

- No limit on the number of re-tips

Contact Monaghan Tooling Group to request a DIATOOL quote now.

DIATOOL Precision Mono-Block Tools

Monaghan Tooling Group is proud to work with DIATOOL, a German tooling manufacturer that specializes in reliable,

high-performance reaming. DIATOOL has more than 35 years of experience in manufacturing and repairing

multi-bladed reamers. Their strengths include:

Monaghan Tooling Group is proud to work with DIATOOL, a German tooling manufacturer that specializes in reliable, high-performance reaming. DIATOOL has more than 35 years of experience in manufacturing and repairing multi-bladed reamers. Their strengths include:

Here are a few successful applications utilizing MK Tools solid carbide drills.

Highest

quality products

Short

delivery times

Competitive

prices

Unique monoblock

design for enhanced

roundness

A wide variety of

cutting materials and

coatings

Near-infinite

reconditioning

Do you need a reliable source for top quality reamers?

Advantages of DIATOOL

DIATOOL reamers offer a multi-blade design with unequal spacing of the cutting edges that produces very round and cylindrical bores compared to conventional reamers and at much higher feed rates than single-point tools.

We offer DIATOOL’s quick turnaround re-tipping to customers with competitor’s products as well. This is a huge advantage for those who do not wish to waste their initial investment but cannot afford the long lead times they are experiencing from DIATOOL’s competitors.

Mono-Block Reaming Success Stories

CASE STUDY

Reaming Blind

Bores in Steel

One of our customers was manufacturing electrical motion control components using a 4-spindle CNC Lathe in high volume.

CASE STUDY

Reaming a

Steering Fork

This manufacturer was reaming a bore on a steering fork made out of case-hardened steel on a horizontal index lathe.

CASE STUDY

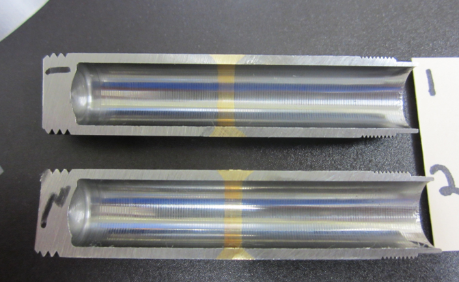

Reaming Tubes for

Medical Application

A manufacturer was machining 6,000 medical tubes per year. The tubes were made of 1.4301 stainless steel.